Selecting the right automatic shrink packaging machine is a decision that impacts every aspect of your packaging operation—from production speed and film efficiency to line uptime and product presentation. Whether you are a manufacturer in the food, cosmetics, or wood industry, or a contract packager managing a high product mix, aligning your machine selection with your product sizes is key to optimizing performance and cost-efficiency.

At Complete Packaging Solutions & Systems Inc. / Kallfass USA, we specialize in high-performance shrink wrapping solutions engineered to adapt to your unique product range—without compromise.

How Does Product Size Influence Machine Selection?

Product size directly determines the type of shrink wrap system you’ll need. If your operation runs a narrow range of uniform product sizes, a dedicated system may be sufficient. However, if your product catalog includes a variety of dimensions—from compact cosmetic items to longer wooden panels—your machine must offer more flexibility.

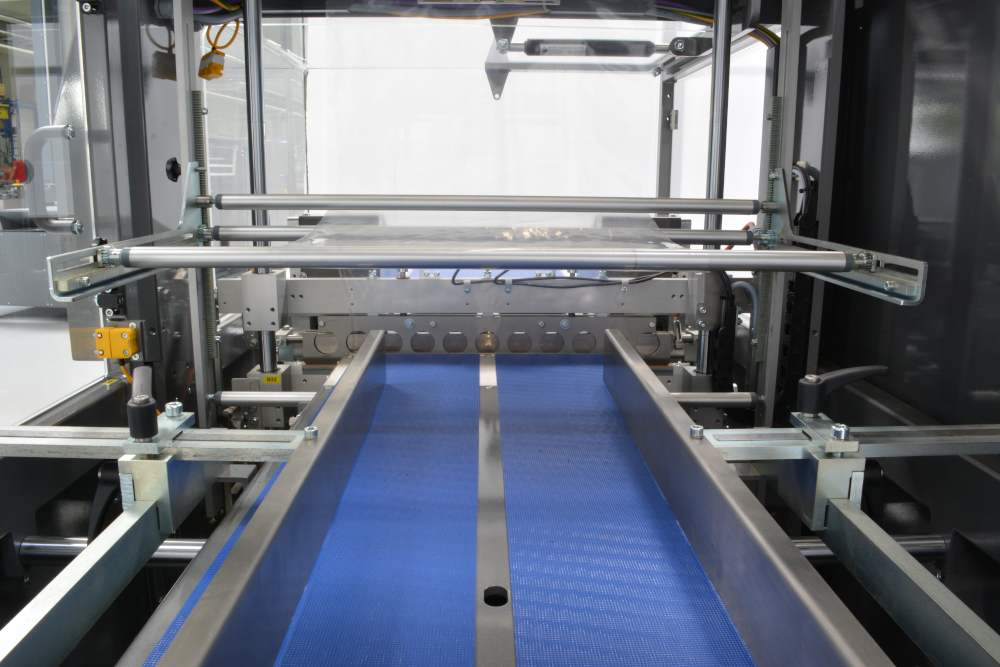

Kallfass machines are built with adjustable guides, servo-driven movement, and automated format switching, allowing seamless transitions between different product sizes. This capability eliminates the need for extensive manual adjustments and reduces changeover downtime, improving throughput.

What Are the Implications of Product Weight and Shape?

Weight and shape are equally critical. Heavy items require robust conveyors, while lightweight or unstable products need controlled feeding and minimal turbulence during wrapping. Irregular shapes often pose sealing challenges and may lead to inconsistent shrink if the system lacks proper product control.

Our automatic wrapping machines integrate motion control technology, ensuring stable product handling through every phase—from sealing to tunnel shrinking. Whether wrapping boxes of paper, trays of baked goods, or uniquely shaped pharmaceutical containers, the machine adjusts dynamically to maintain accuracy and consistency.

Is Your Line Capable of Supporting High-Speed Output?

If you’re producing thousands of units per shift, you need a fully automatic wrapping machine that can maintain that pace without breakdowns or bottlenecks. Machine speed isn’t just about the rate per minute—it’s also about how well the system handles product spacing, rejects errors, and maintains seal integrity under pressure.

Kallfass systems consistently deliver speeds ranging from 25 to 80 products per minute, depending on the product size and film type. With a track record of over 98.5% uptime, our equipment supports uninterrupted production and helps meet even the most aggressive output targets.

Do You Need a System That Supports Frequent Product Changeovers?

Frequent changeovers are a reality for many operations—especially in contract packaging environments. Downtime during these transitions adds up fast, affecting profitability and labor efficiency.

Kallfass USA machines are equipped with fully programmable product memories. With intuitive operator interfaces, users can store and retrieve settings for multiple products. This means your operators can change product formats in minutes—no mechanical intervention, no reprogramming in the field.

Also Read :

Why Side Seal Shrink Wrapping is Ideal for Bakery Products

How Does Side Seal Shrink Wrapping Minimize Downtime in Bakery Operations?

Which Film Types Should the Machine Handle?

A capable shrink wrap system must support a range of films to suit different applications. Whether you’re using thin, retail-friendly polyolefin or rugged polyethylene for industrial protection, the machine must deliver consistent performance without film waste.

Kallfass automatic shrink packaging machines are engineered to run all film types equally—without manual film path adjustments. This versatility helps companies manage inventory, reduce material switching time, and avoid film-related downtime. Our machines also reduce film usage by up to 15% thanks to precise cutting and sealing control.

Can the System Integrate With Your Existing Line?

Integration is critical if you’re upgrading from a semi automatic shrink wrapping machine or expanding an automated production line. Your shrink wrap machine must communicate with upstream feeders and downstream packers in real time.

Kallfass machines are built with integration in mind. Featuring modular design, PLC control compatibility, and adjustable conveyor speeds, our systems align effortlessly with your production environment—ensuring smooth synchronization without reengineering your layout.

What Are the Key Technical Features to Consider?

While performance is a top priority, long-term ownership costs depend heavily on system efficiency and reliability. When comparing shrink wrap machines, look for:

- No compressed air requirements – reducing maintenance and utility costs

- Energy regeneration systems – improving sustainability and reducing operational expenses

- Servo-driven motion control – offering pinpoint accuracy and fewer moving parts

- No field programming required – ensuring ease of operation and minimizing technician dependency

- Self-centering film feed systems – for consistent material alignment and waste reduction

These features are standard across all Kallfass models—ensuring every system delivers not only precision but also long-term return on investment.

How Do Shipping, Installation, and Support Factor In?

Proper installation is essential to get your system running at peak efficiency. Whether your machine is shipping from a domestic facility or overseas, logistics must be carefully coordinated. Some units may require forklifts or dock-height receiving. Installation should also include comprehensive training.

Complete Packaging Solutions & Systems Inc. / Kallfass USA offers complete support—from freight planning to installation and post-sale training. Our technicians are based in North America, with spare parts and remote diagnostic tools on hand. Downtime is minimized, and productivity is preserved.

What Are the Payment Options and Lead Times?

Lead times vary depending on the configuration and level of customization required. While some fully automatic wrapping machines may be built-to-order, stock options are occasionally available. Financing options—including leasing with service agreements—are also worth exploring for businesses managing capital expenditures.

We work closely with clients to provide clear delivery timelines, payment plans, and ongoing technical support. Our transparent process ensures you receive not only the right system but also the service to support it throughout its lifecycle.

Why Partner With Complete Packaging Solutions & Systems Inc. / Kallfass USA?

For over a decade, Complete Packaging Solutions & Systems Inc. / Kallfass USA has delivered high-performance shrink wrap machines that go beyond automation. Our systems are engineered for precision, durability, and unmatched flexibility. Trusted by industry leaders across North America, we serve manufacturers in:

- Food and bakery production

- Wood product processing

- Cosmetics and pharmaceuticals

- Contract packaging and printing

Every machine is backed by expert consultation, robust after-sales support, and a commitment to performance over price.

Make the Right Choice for Long-Term Efficiency

Investing in the right automatic shrink packaging machine means more than streamlining your packaging process—it means setting your business up for scalable, sustainable success. From accommodating product size variations to handling multiple film types and reducing material waste, your equipment should support your goals—not limit them.

At Complete Packaging Solutions & Systems Inc. / Kallfass USA, we’re here to help you select the best system for your operation. Whether you’re upgrading from a semi automatic shrink wrapping machine or moving toward full-scale automation, we’ll guide you every step of the way.

Contact Complete Packaging Solutions & Systems Inc. / Kallfass USA today for a custom consultation.