Can an Intermittent Motion Sealer Reduce Film Waste?

Shrink packaging is a critical process for manufacturers and contract packagers across North America. As companies strive to minimize costs and maximize efficiency, the choice of shrink wrap equipment can make a significant difference. One question that often arises is whether an intermittent motion side sealer can help reduce film waste while maintaining high-quality packaging.

What Is an Intermittent Motion Side Sealer?

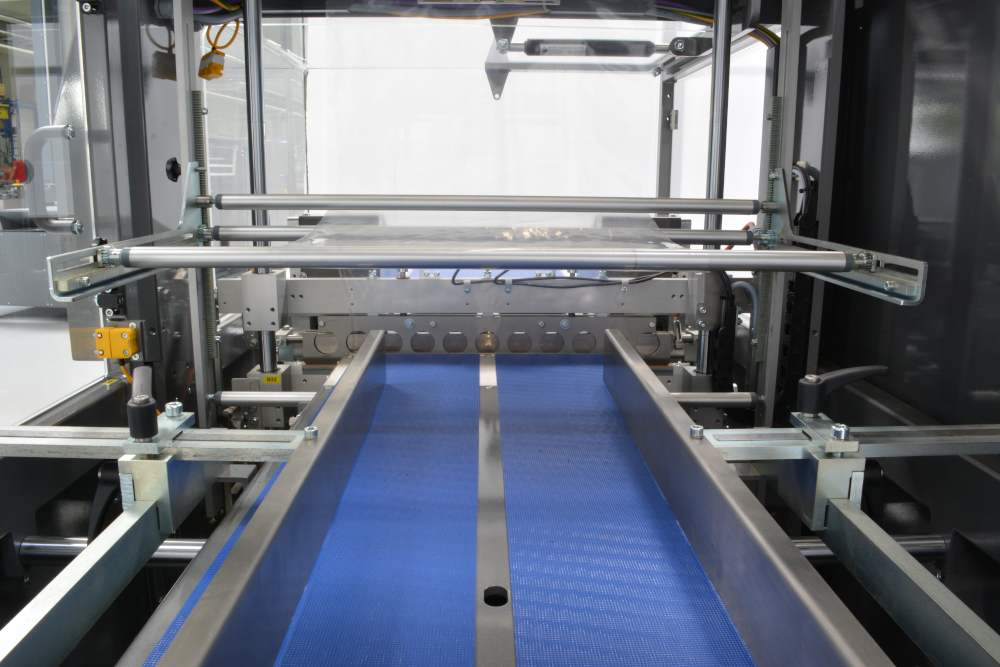

An intermittent motion side sealer is a fully automatic packaging machine designed for shrink wrapping a wide variety of products. Unlike continuous motion machines, which operate non-stop, intermittent motion side sealing machines pause momentarily between each sealing cycle. This start-and-stop action allows the product to remain stationary during the sealing process, ensuring precise seals and consistent package quality.

These machines are highly flexible and can handle products of different sizes and shapes. Their robust construction, often featuring heavy-duty steel frames, ensures quiet operation and minimal vibration, making them a favorite on the packaging line. With modern motion control technology, intermittent motion side sealers are engineered to deliver professional results without the need for extremely high output rates.

How Does an Intermittent Motion Side Sealer Work?

Intermittent motion side sealers function by stopping the conveyor belt for each package, allowing the sealing bar to make a clean, accurate seal. The machine then advances the product for the next cycle. This method is ideal for operations that do not require the high speeds of continuous motion systems but still demand reliable, high-quality packaging.

The fully automatic intermittent motion side sealer is equipped with intelligent controls for adjusting temperature, airflow, and conveyor speed. This ensures optimal heat transfer and shrink results, regardless of the product’s size or shape. Encoder controls guarantee precise bag length and product placement, eliminating the need for manual timers or counters.

Also Read :

How Do Kallfass Side Sealers Handle High-Speed Packaging Without Sacrificing Quality?

How Do You Integrate a Side Sealer into an Automated Packaging Line?

Can These Machines Help Reduce Film Waste?

Reducing film waste is a top priority for packaging operations. While continuous motion side sealers are known for their superior film savings due to servo motor controls, intermittent motion side sealers also offer notable advantages. Modern intermittent motion side sealing machines, such as those from Kallfass, utilize advanced motion control technology to optimize film usage and minimize excess material.

The ability to adjust sealing parameters and product spacing ensures that only the necessary amount of film is used for each package. This precision helps prevent unnecessary film tails and reduces overall material consumption. Additionally, the compact design and efficient heat transfer of these machines contribute to faster heat-up times and lower energy use, further supporting cost savings.

What Are the Main Benefits of Using an Intermittent Motion Side Sealer?

- Versatility: These machines can package a wide range of products, including items of varying sizes and shapes. This makes them suitable for industries such as food, bakery, cosmetics, pharmaceuticals, and printing.

- Lower Operating Costs: With advanced motion control, Kallfass intermittent motion side sealers average 30% lower operating costs compared to competing models.

- Quality and Consistency: The stationary sealing process ensures perfect shrink results and reduces the risk of product shifting or damage during packaging.

- Ease of Use: Product changeovers are quick and straightforward, often taking just seconds. Operators can easily adjust machine settings without specialized programming knowledge.

- Quiet and Durable: Heavy-duty steel frames and solid construction mean these machines run quietly and are built to last, providing a more comfortable work environment.

When Should You Choose an Intermittent Motion Side Sealer Over Other Options?

Is an intermittent motion side sealer the right fit for every operation? The answer depends on your production needs and goals.

If your business does not require extremely high throughput but values flexibility, precision, and cost-effectiveness, a fully automatic intermittent motion side sealer is an excellent choice. These machines are ideal for manufacturers and contract packagers who handle a diverse range of products and want to maintain professional packaging standards without the higher investment of continuous motion machines.

However, if your operation demands maximum speed and minimal product spacing, a continuous motion side sealer may offer greater film savings and efficiency. For many small to mid-sized businesses, though, the intermittent motion side sealing machine strikes the perfect balance between performance and affordability.

How Does Kallfass USA Deliver Value With Intermittent Motion Side Sealers?

Complete Packaging Solutions & Systems Inc. / Kallfass USA specializes in high-end, fully automatic intermittent motion side sealers designed to meet the needs of North American manufacturers. Their systems feature cutting-edge motion control, energy regeneration, and do not require compressed air, ensuring performance, durability, and precision across a wide range of industries.

Kallfass machines are engineered for uptime exceeding 98.5%, easy film switching, and seamless integration into existing packaging lines. With the ability to run all films equally and eliminate spacing issues, these machines help businesses save 10–15% on materials while maintaining top-tier packaging quality.

What Should You Consider Before Investing in an Intermittent Motion Side Sealer?

Before making a decision, consider the following:

- Product Variety: Do you package items of different sizes and shapes?

- Output Requirements: Is your throughput moderate rather than extremely high?

- Budget Constraints: Are you seeking a cost-effective solution without sacrificing quality?

- Operational Efficiency: Do you need quick changeovers and minimal downtime?

- Material Savings: Is reducing film waste and operating costs a priority?

If you answered yes to most of these questions, a fully automatic intermittent motion side sealer from Kallfass USA could be the ideal solution for your business.

Ready to Optimize Your Packaging Line?

Discover how Complete Packaging Solutions & Systems Inc. / Kallfass USA can help you achieve efficient, cost-effective, and professional shrink packaging. Contact us today for expert guidance on the best intermittent motion side sealer for your needs!