How Do Shrink Wrap Machines Improve Warehouse Safety and Efficiency?

Shrink wrap machines are essential tools in modern warehouses, enhancing both safety and efficiency. These machines tightly seal products in durable shrink film, protecting them from dust, moisture, and damage. This secure packaging minimizes product loss caused by contamination and mishandling, creating a safer warehouse environment. Additionally, automated shrink wrap machines streamline the packaging process to speed up throughput and reduce labor requirements.

What Are the Key Benefits of Using Shrink Wrap Machines in Warehouse Operations?

Shrink wrap machines offer multiple advantages that improve warehouse productivity and safety:

- Product Protection and Stability: Shrink-wrapped goods are securely bundled, reducing the risk of shifting loads that can cause accidents during handling or transport. This protection also guards against dust, moisture, and tampering.

- Space Optimization: Tight shrink wrapping minimizes the volume of packaged products compared to traditional packaging, allowing warehouses to maximize storage capacity and reduce floor space usage.

- Labor and Time Savings: Automatic shrink packaging machines accelerate wrapping speeds and reduce manual labor. They automate film placement, sealing, and heat application, enabling faster packaging rates with fewer workers.

- Cost Efficiency: By reducing film waste and eliminating the need for additional packing materials, shrink wrap machines help lower packaging costs. Many machines offer 10-15% material savings through precise film control.

How Does an Automated Shrink Wrap Machine Increase Throughput and Performance?

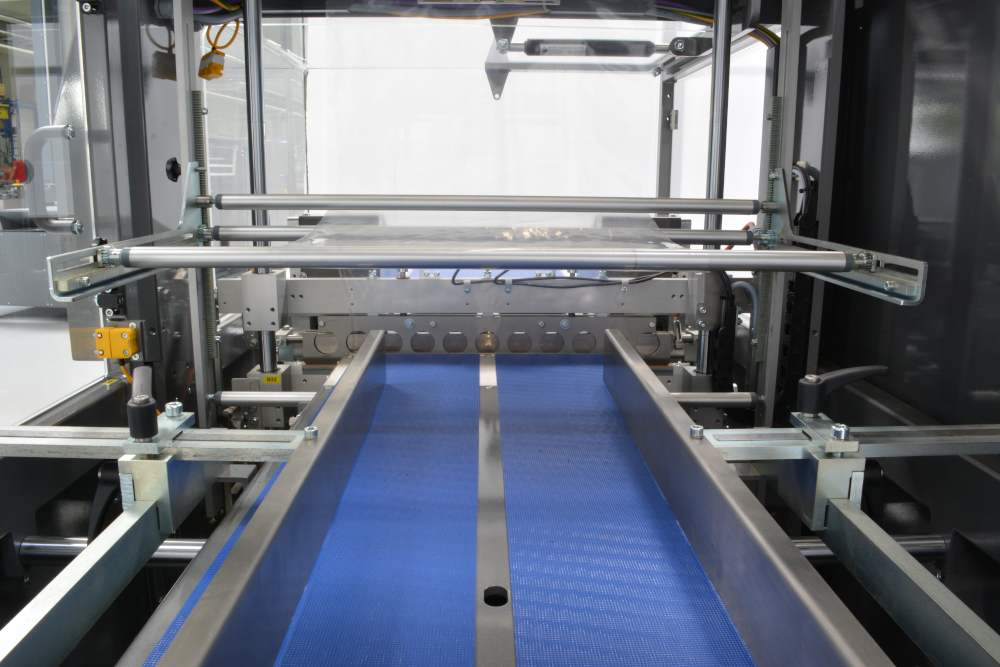

An automated shrink wrap machine uses advanced technology to package products quickly and reliably. These machines wrap items with shrink film that passes through a heated tunnel, causing the film to tightly conform to the product’s shape. Motion control technology and energy regeneration features optimize operations and uptime, helping meet high demand with minimal downtime. The plug-and-play design requires no field programming, providing easy integration in warehouse production lines.

Also Read :

How to Maintain Peak Performance in Automatic Shrink Wrapping Machines

How Does Shrink Wrap Packaging Enhance Product Presentation and Branding?

Which Industries Benefit Most from Automatic Shrink Packaging Machines?

Industries such as food, bakery, wood, cosmetics, pharmaceuticals, and printing rely on automated shrink wrap machines. These machines handle diverse product sizes and shapes while delivering tamper-proof, attractive packaging. Manufacturers and contract packagers benefit from improved speed, flexibility, and sustainability, making shrink packaging an ideal automation solution for high-volume operations.

Why Choose Complete Packaging Solutions & Systems Inc. / Kallfass USA for Shrink Wrap Machines?

Complete Packaging Solutions & Systems Inc. / Kallfass USA specializes in automatic shrink wrap machines engineered for durability, performance, and precision. Their systems feature motion control technology, energy regeneration, and require no compressed air. With 98.5%+ uptime, seamless film switching, and no field programming needed, Kallfass machines deliver reliable packaging automation. Trusted by manufacturers across multiple industries, Kallfass solutions save 10–15% on materials, eliminate spacing issues, and provide unmatched productivity.

For reliable, high-performance automatic shrink wrap machines, contact Complete Packaging Solutions & Systems Inc. / Kallfass USA today to optimize your packaging safety and efficiency.