How Side Sealers Reduce Contamination in Bakery Packaging

When it comes to packaging delicate bakery goods, protecting the product from contamination is crucial. Crumbs, toppings, and flour are naturally present in any bakery environment, but they can easily interfere with packaging seals. Choosing the right shrink wrap machine for food plays a major role in maintaining freshness, hygiene, and product appeal.

Let’s dive deeper into how side sealers are transforming bakery packaging with better protection and efficiency.

Why Is Contamination a Challenge for Bakery Packaging?

Bakery products, from bread to pastries, are fragile. Crumbs and toppings often fall during the packaging process. If they get into the sealing area, they can compromise the integrity of the package, leading to open seals and product spoilage.

Traditional lap sealers are more prone to these issues because they seal along the bottom where debris collects. An unreliable seal exposes the product to contamination, reduces shelf life, and damages customer trust.

This is where using a shrink wrap machine for food with side sealing technology becomes a game-changer.

How Do Side Sealers Minimize Packaging Contamination?

Side sealers eliminate many of the risks associated with conventional lap seal methods.

Instead of sealing at the bottom, side sealers create a strong, consistent seal on the side of the package, keeping the bottom free from sealing issues caused by debris.

Here’s how side seal shrink wrap machines for food packaging make the difference:

- Debris Avoidance: Since side sealing happens away from the bottom, crumbs and particles don’t interfere with the seal.

- Consistent Seals: Side sealers deliver uniform, positive seals even in environments with varying levels of debris.

- Quick Detection: Any issues with side seals are easier to spot and fix, ensuring defective packages don’t reach customers.

- Flexible Film Usage: Side sealers can handle different film sizes, saving time and reducing the need for large film inventories.

What Additional Benefits Do Side Sealers Offer for Bakery Packaging?

Beyond contamination control, side sealers provide several operational advantages, making them ideal for busy bakeries:

- Simple Changeovers: Easily switch between different product sizes without complex machine adjustments.

- Less Film Waste: Side sealing typically uses less film than lap sealing, leading to material cost savings.

- Durable Packaging: Strong side seals help protect bakery items during shipping and shelf display.

- Fast Setup: With fewer mechanical change parts required, bakeries enjoy quicker transitions between product runs.

Choosing an automatic food wrapping machine with side sealing technology helps bakeries maximize efficiency while maintaining the highest packaging quality.

Upgrade Your Bakery Packaging with Trusted Expertise

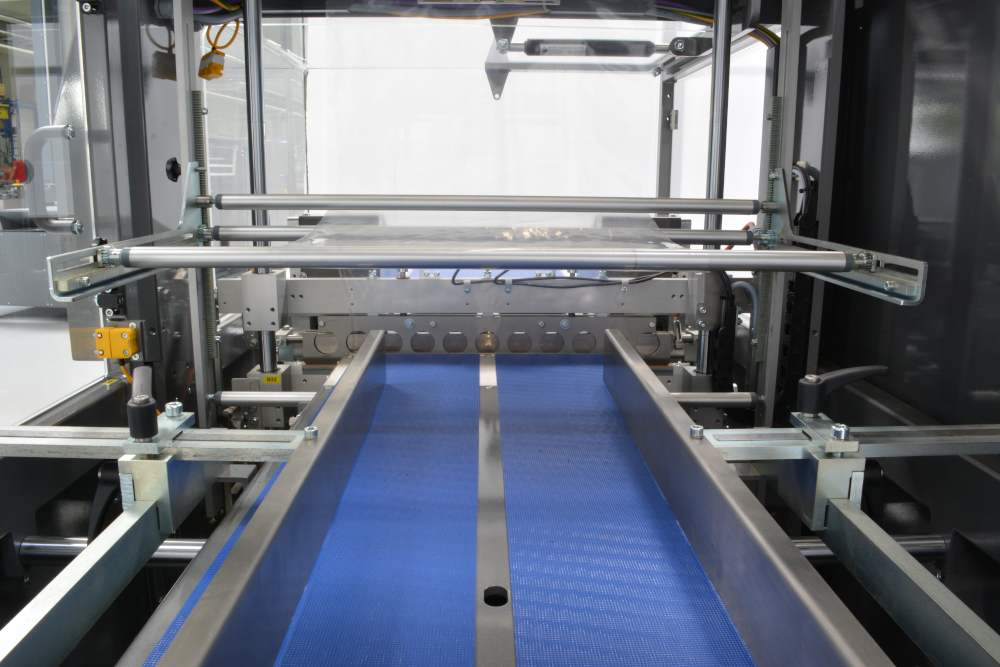

At Complete Packaging Solutions & Systems Inc. / Kallfass USA, we help manufacturers rethink what’s possible in packaging. Our high-performance systems—ranging from automatic shrink wrap machines to heat tunnels and sleeve wrappers—are engineered for maximum uptime, seamless film flexibility, and unmatched durability.

Our technology features energy regeneration, no compressed air requirements, and effortless film switching. Whether you’re packaging artisan bread or high-volume baked goods, Kallfass Industrial shrink wrap machines deliver solutions that protect product quality and streamline your production line.

Take the first step toward superior bakery packaging—partner with Complete Packaging Solutions & Systems Inc. / Kallfass USA and experience precision without compromise.

Also Read:-

Why Are Gluten-Free and Allergen-Free Bakeries Choosing Side-Seal Shrink Wrapping?

What Packaging Challenges Do Bakeries Face That Side-Seal Shrink Wrap Solves?