What Controls and Adjustments Optimize Shrink Tunnel Performance?

Efficient packaging is more than sealing products—it’s about ensuring they look flawless and arrive in perfect condition. For manufacturers and packaging companies, heat shrink tunnels are essential for achieving that balance of presentation and protection. However, getting the most from a heat tunnel shrink wrap machine depends on precise controls and adjustments.

How Does Temperature Control Impact Results?

Temperature is the most critical setting in a heat shrink tunnel machine. Too little heat results in loose or uneven film shrinkage. Excess heat can damage products or cause the film to over-shrink. The goal is to match the tunnel temperature to the film type and product size.

Modern shrink tunnel machines from Complete Packaging Solutions & Systems Inc. / Kallfass USA offers precision temperature regulation, allowing operators to set and maintain the perfect heat level. This ensures consistent packaging quality, cycle after cycle.

Why is Conveyor Speed an Important Adjustment?

Conveyor speed determines how long a product remains inside the tunnel. Faster speeds mean shorter heat exposure, while slower speeds allow for more shrink time. The right balance avoids both under- and over-shrinking.

For example, a heat tunnel machine used to package lightweight bakery goods may require a different speed than one wrapping heavy wooden products. Adjustable speed controls allow operators to fine-tune the process for optimal results.

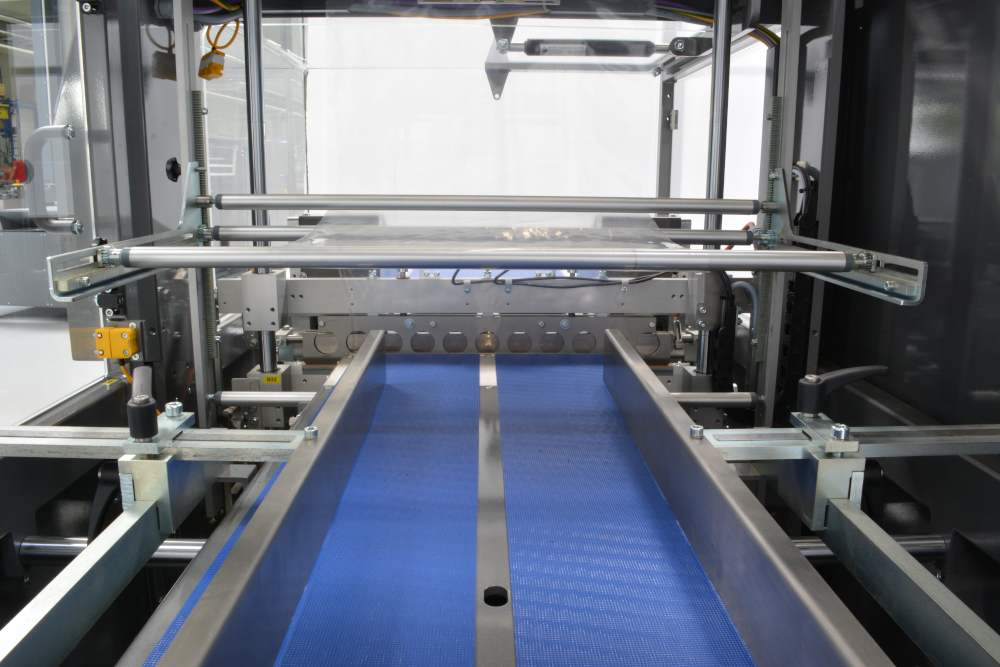

What Role Does Airflow Play in Shrink Quality?

Airflow inside the tunnel distributes heat evenly around the product. Proper circulation ensures every side of the package receives consistent heat. Uneven airflow can leave wrinkles or cold spots in the film.

Advanced tunnels use adjustable airflow controls, enabling operators to direct heat exactly where needed. This is particularly important for irregularly shaped items or delicate products.

Which Other Settings Affect Packaging Efficiency?

Several additional adjustments contribute to high-quality shrink wrapping:

- Film Type Compatibility – Matching film properties to tunnel settings avoids waste and improves product appearance.

- Energy Management – Efficient tunnels use energy regeneration to lower operating costs.

- Maintenance Access – Easy-to-clean and accessible components reduce downtime.

Also Read :

Belt-Driven vs. Chain-Lugged In-Feeds: Which Side Sealer Setup is Right for You?

How Do You Set Up a Side Sealer Correctly for Optimal Packaging?

How Do Modern Tunnels Reduce Costs and Improve Performance?

High-end systems from Complete Packaging Solutions & Systems Inc. / Kallfass USA integrates features that save materials and energy without compromising quality. These include:

- Motion control technology for smooth product handling.

- Film versatility with quick changeovers.

- No compressed air requirement, lowering maintenance costs.

With 98.5%+ uptime, these tunnels maximize productivity for industries like food, bakery, cosmetics, pharmaceuticals, printing, and wood manufacturing.

Why Choose Complete Packaging Solutions & Systems Inc. / Kallfass USA?

Choosing the right heat shrink tunnel machine means partnering with a company that understands packaging performance. Kallfass USA delivers precision-engineered systems that run all films equally, eliminate spacing issues, and save up to 15% on materials. Their solutions integrate seamlessly with existing lines, ensuring quick setup and minimal disruption.

Upgrade your packaging line today—contact Complete Packaging Solutions & Systems Inc. / Kallfass USA for high-performance heat shrink tunnels and turnkey packaging automation.