What Safety and Sanitation Features Matter Most in Pharma Shrink Wrap Machines?

Packaging in the pharmaceutical industry demands more than just efficiency. It requires equipment that guarantees safety, compliance, and hygiene while maintaining production speed. A shrink wrapping machine for pharmaceutical products must deliver precise seals, protect against contamination, and preserve the product’s integrity from the production floor to the consumer’s hands.

How Do Shrink Wrap Machines Maintain Product Safety?

Safety in pharmaceutical packaging begins with a tamper-evident seal. A high-quality shrink wrapping machine for pharmaceutical products ensures airtight wrapping that visibly indicates if a package has been opened or altered. This is essential for meeting regulatory requirements and maintaining consumer trust.

These machines are also engineered to handle delicate pharmaceutical items—such as blister packs, bottles, or medical devices—without damaging them. By using precise temperature control and even heat distribution, the seal is secure without compromising the product’s quality.

Why Is Sanitation Critical in Pharmaceutical Packaging Equipment?

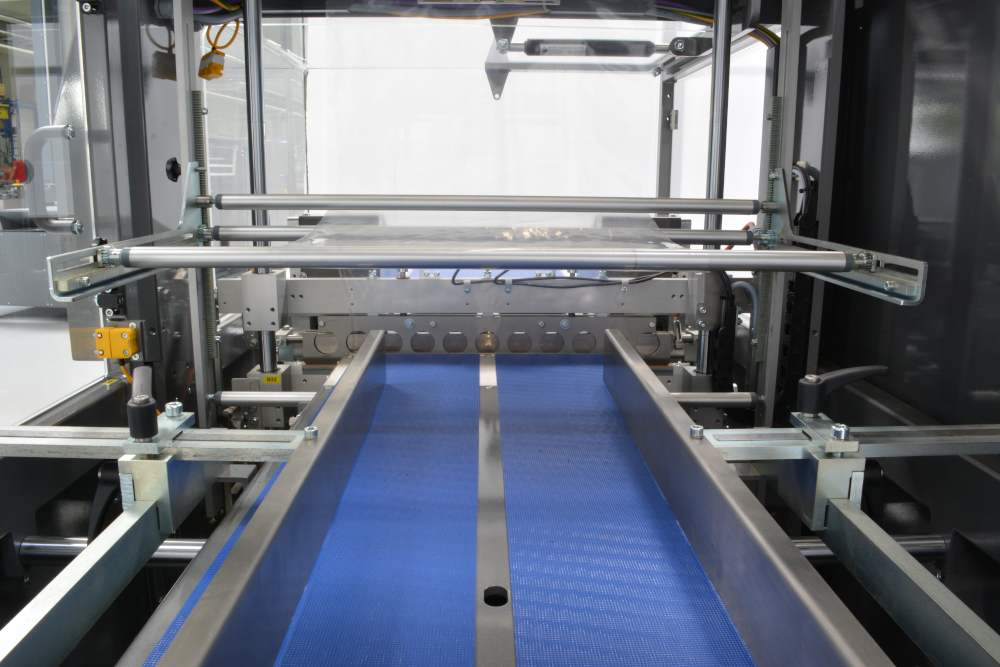

Sanitation is non-negotiable in pharmaceutical production. Contamination can lead to product recalls, brand damage, and health risks. That’s why leading shrink wrapping machines in this sector are designed with:

- Smooth, easy-to-clean surfaces that prevent residue buildup.

- Stainless steel construction for corrosion resistance and compliance with hygiene standards.

- Tool-free disassembly for quick sanitation between production runs.By minimizing dirt traps and enabling thorough cleaning, these machines reduce the risk of cross-contamination.

What Role Does Tamper Evidence Play in Regulatory Compliance?

Tamper-evident packaging is a core requirement in the pharmaceutical industry. It’s not just about sealing the product—it’s about providing visible proof that it hasn’t been opened. A shrink wrapping machine for cosmetic products and pharmaceutical packaging achieves this with high-clarity films that tightly conform to the product’s shape, making any breach immediately noticeable.

This is crucial for compliance with FDA regulations and GMP guidelines, which require packaging methods that protect against tampering and contamination.

How Do Advanced Machines Improve Production Efficiency Without Compromising Hygiene?

Modern pharmaceutical packaging must balance speed with sanitation. Advanced shrink wrapping systems—like those from Complete Packaging Solutions & Systems Inc. / Kallfass USA—feature automated film feeding, motion control technology, and no compressed air requirements. This combination ensures high-speed output while keeping maintenance and cleaning straightforward.

These systems can also switch between film types without adjustments in the field, saving time and reducing material waste. The result is consistent, high-quality packaging with less downtime.

Also Read :

How to Maintain Peak Performance in Automatic Shrink Wrapping Machines

How Does Shrink Wrap Packaging Enhance Product Presentation and Branding?

Why Choose Specialized Equipment for Cosmetics and Pharmaceuticals?

Cosmetics and pharmaceuticals share a need for precise, attractive, and compliant packaging. Whether sealing beauty kits or medical supplies, a shrink wrapping machine for cosmetic products delivers professional presentation alongside robust protection.

By investing in machines built for these industries, businesses benefit from:

- Versatility to handle various product sizes and shapes.

- Consistent seals that meet industry safety and hygiene standards.

- Material savings of up to 15% through efficient film use.

Ensuring Packaging Excellence in Pharmaceuticals

In pharmaceuticals, packaging is more than a finishing step—it’s a safeguard for public health and brand integrity. Choosing a machine with the right safety and sanitation features ensures compliance, efficiency, and consumer confidence.

Complete Packaging Solutions & Systems Inc. / Kallfass USA delivers premium shrink-wrap equipment engineered for performance, hygiene, and precision—trusted by leading pharmaceutical and cosmetic manufacturers.

Ready to elevate your pharmaceutical packaging? Contact Complete Packaging Solutions & Systems Inc. / Kallfass USA today for a custom shrink-wrap solution that meets the highest safety and sanitation standards.